DMUCC - series

CHARACTERISTICS OF THE ESCODISC DMUCC SERIES COUPLINGS

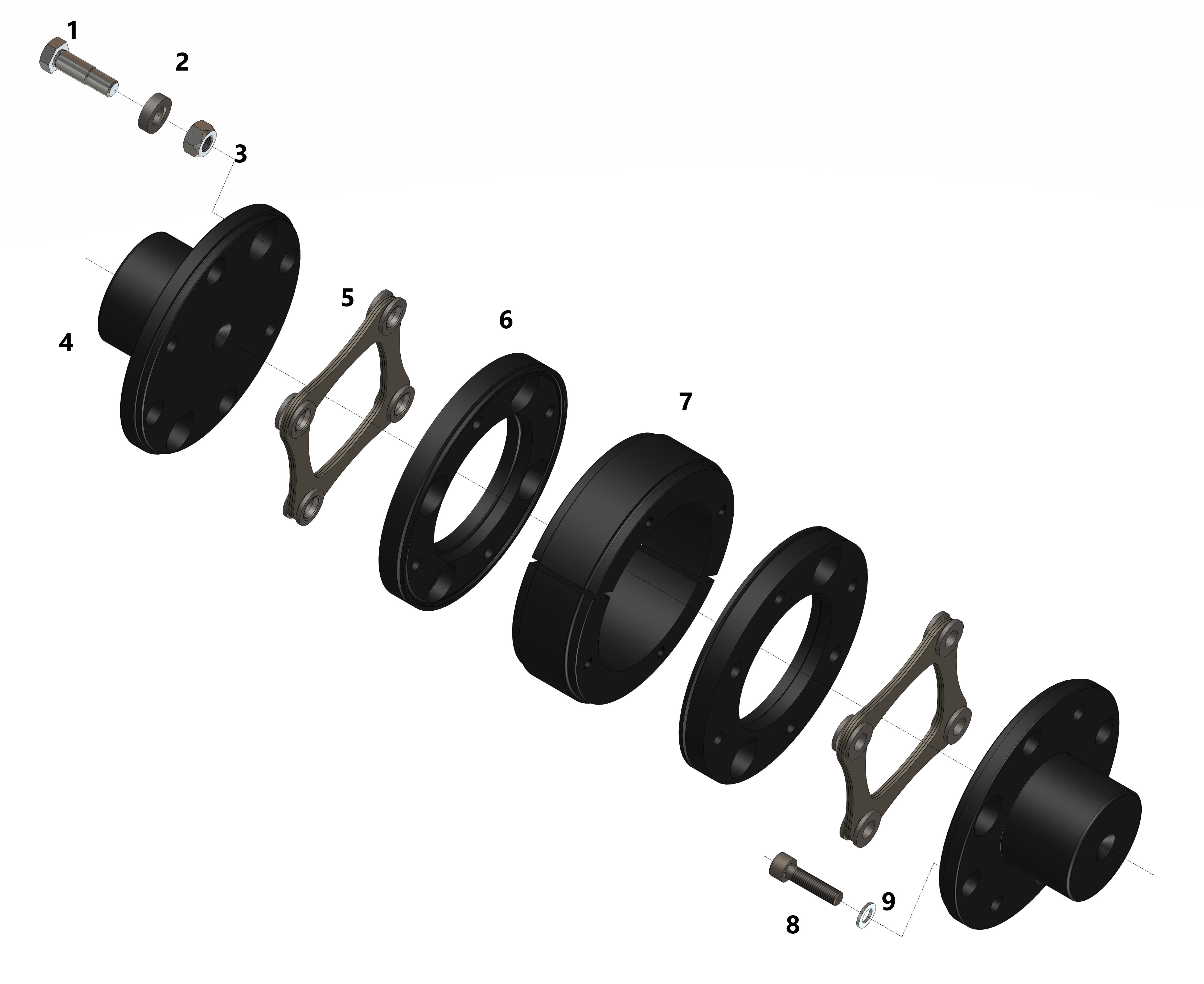

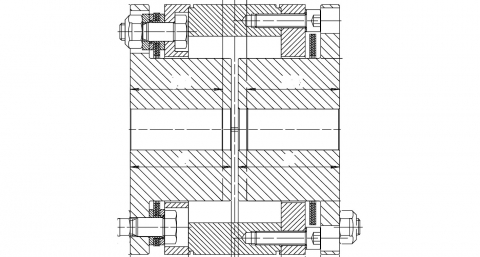

Disc couplings are of an all-metal, non-lubricated design and are torsionally stiff. The torque is transmitted by means of discs, which are alternatively mounted (on the same bolt circle) to the drive and driven flange of the disc pack assembly.

The misalignment capacity depends on the pack thickness, the disc material, the amount of drive bolts and the free span of the material between the drive bolts.

The total torque capacity depends on the disc pack thickness, total number of drive bolts and their bolt circle.

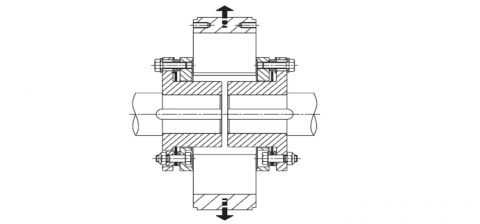

Disc couplings will in most cases have two flexible elements and a spacer. As all parts are positively connected, this disc coupling ensures good inherent balancing properties and is hence often used at motor speeds without additional balancing.

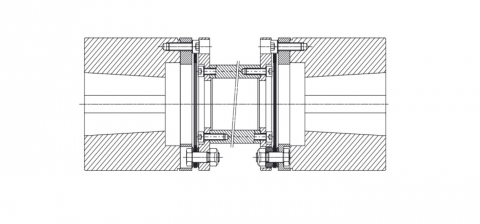

The Escodisc DMUCC series has a close coupled design with a split spacer. It's high torque, bore and it's misalignment capacity makes it an ideal maintenance-free alternative for close coupled gear and elastic type couplings and can be modified in such a way that replacement of gear and elastic couplings is possible without modifications to an existing installation. Its split spacer design allows a disconnection of two machines and replacement of the disc pack without any axial displacement of the connected machines. The Escodisc DMUCC series is the ideal solution for applications up to 29,600 Nm (and larger upon request) with its high degree of natural inherent balance up to size 85.

THE ESCO ADVANTAGE

The Escodisc DMUCC series offers:

-

Unitized disc pack that can be replaced on site

-

Discs with an optimized shape unitized as a pack

-

Fillers avoiding contact between discs hence no fretting corrosion

-

Coasting down torque transmission guaranteeing in case of disc pack failure

-

Easy assembly and disassembly

Alike the other Escodisc couplings, the Escodisc DMUCC series also offers:

-

Optimized shaped stainless-steel discs for equal load distribution

-

AISI 301 Full hard stainless-steel discs

-

Special plated hardware

-

Precisely drilled and reamed flange holes

-

Black oxyded overall steel parts, oiled for protection

-

High torque and high continuous misalignment capacity

-

Maintenance free

-

Very low and predictable reaction forces on associated equipment

-

No disc buckling, no fretting corrosion between the discs

-

Temperature range -40°C to 270°C

-

No problems in dirty and corrosive environments due to the use of stainless steel discs and protected bolts

Availabilities

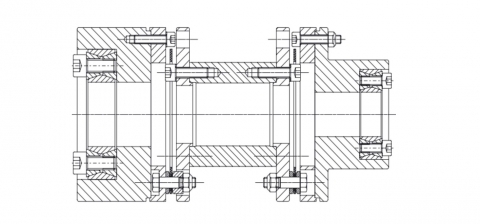

DMUCC

Close coupled

Other types available - on request

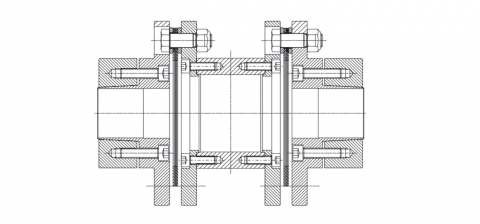

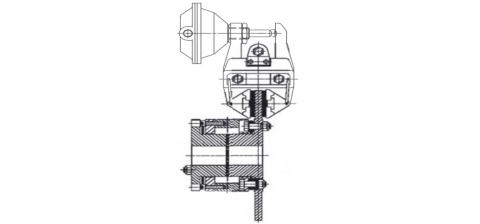

DMUCCBD

With integrated brake disc

Split spacer

Split spacer length can be suited within limits