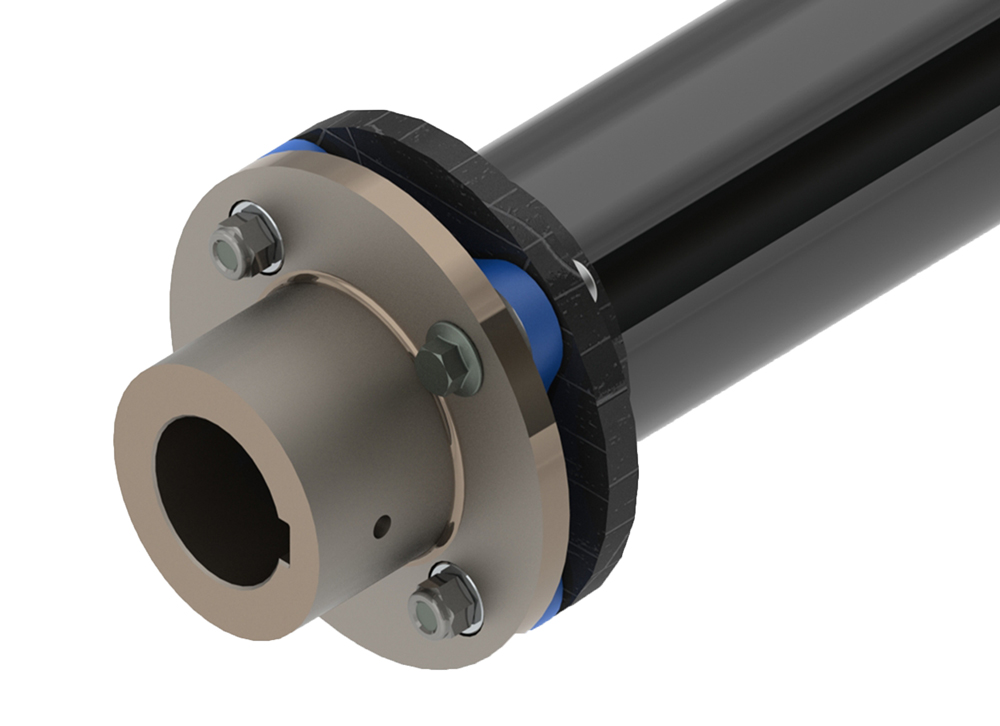

DISC COUPLINGS - COMPOSITE SERIES

CHARACTERISTICS OF THE ESCODISC COMPOSITE SERIES COUPLINGS

The ESCO Composite is a state-of-the-art disc-type flexible coupling designed for infinite life and built out of advanced composite material that confer unparalleled light weight, high strength, corrosion and ultra-violet resistance to the coupling.

The ESCO Composite coupling has been designed with the customer’s interest in mind and it provides significant benefits over alternative transmission solutions.

The disc type flexible elements are made from a combination of stainless-steel bushings, advanced composite disc links and a urethane encapsulation to provide a unitized assembly with a theoretical infinite fatigue life. The flexible elements are rated for 1 Degree misalignment and carry a 4 times peak overload rating when applied at 2.0 service factor.

The hubs and hardware are made from stainless steel for added corrosion protection in aggressive environments. The combination of high peak overload capacity and high strength composites makes this product a heavy – weight title contender despite its light weight. The floating spacer shafts are made from Graphite and /or E-glass fibres embedded in an epoxy matrix. The epoxy resin is filled with a UV protective additive and cured at high temperature. This system provides corrosion resistance that exceeds stainless steel. There are five sizes of flexible elements that range from 75K W to 675 KW to serve most electric motor driven applications. These flexible elements are combined with matching hubs, hardware kits and floating spacer shafts to provide the most economical selection for given application.