FTRN - series

Characteristics of the Escogear FTRN series couplings

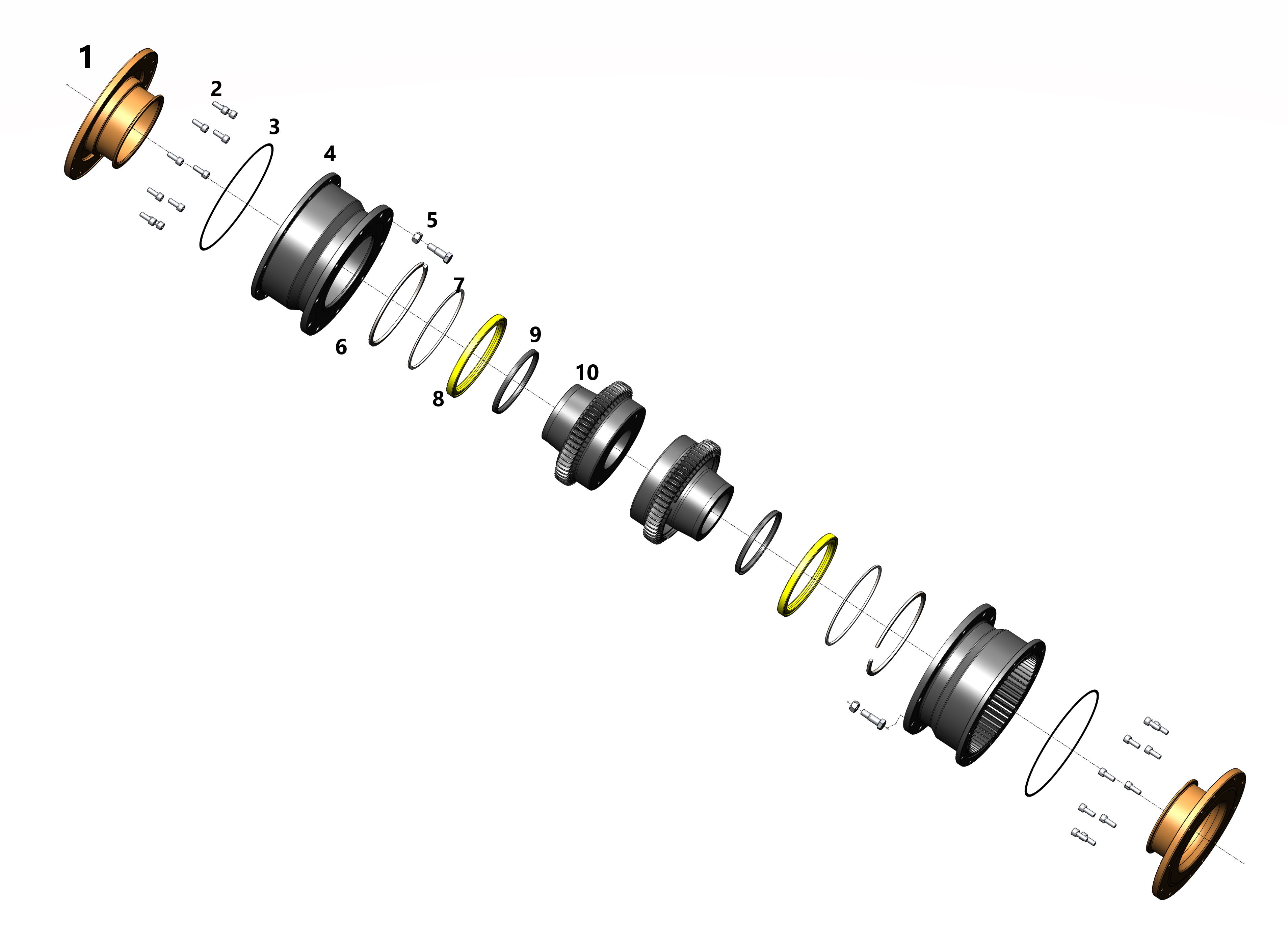

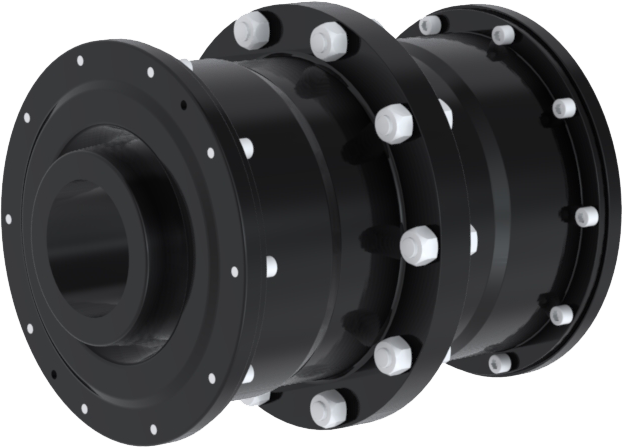

Gear couplings are lubricated type couplings with the highest torque capacity. The Escogear FTRN series couplings basically consist of two hubs with external teeth connected by means of two internally geared sleeves or so called flanges.

Gear couplings in general accommodate angular and axial misalignments. Where the angular misalignment is determined by the gearing geometry,the axial capacity varies according to the manufacturer and can be large. The possibility of selecting a specific gear configuration enables specific challenges to be met.

For traction applications, the couplings need to transmit high torques and to accommodate high angular as well as axial misalignments and operate at very high rotating speeds. As these couplings are used in passenger transport systems, quality and safety requirements are crucial design criteria.

The Escogear FTRN series is robust and reliable. It was developed especially to meet the highest demands of the rail sector. It is generally supplied as two identical halves and 1 set of fasteners.

The Esco advantage

The Escogear FTRN series offers:

-

High torque capacity & important angular misalignment allowing the coupling to operate under combined load, speed and misalignment conditions

-

High bore capacity

-

Light weight

-

The highest manufacturing quality & long coupling life guaranteed

-

A Multicrown gear shape

-

Perfect homokinetic torque transmission

-

Reduced backlash

-

Perfect gear top centering

-

Components marked and identified

-

Extremely low assembly time (and cost)

-

A design life of 30 years minimum

-

Components supplied by balanced half coupling

-

Factory grease filled coupling

-

Easy maintenance and logistics

-

The option of being supplied painted

-

Zinc-coated body-fitted flange connection bolts avoiding fretting corrosion in the flange bores

-

Excellent protection of components

-

ISO 9001 certification and IRIS certification (in process)

-

High misalignment capacity up to 7° for high rotating speeds up to 8,000rpm

-

No lateral vibrations

-

Positive positioning of the sleeve movement

-

No springs: avoiding axial and lateral vibration problems